|

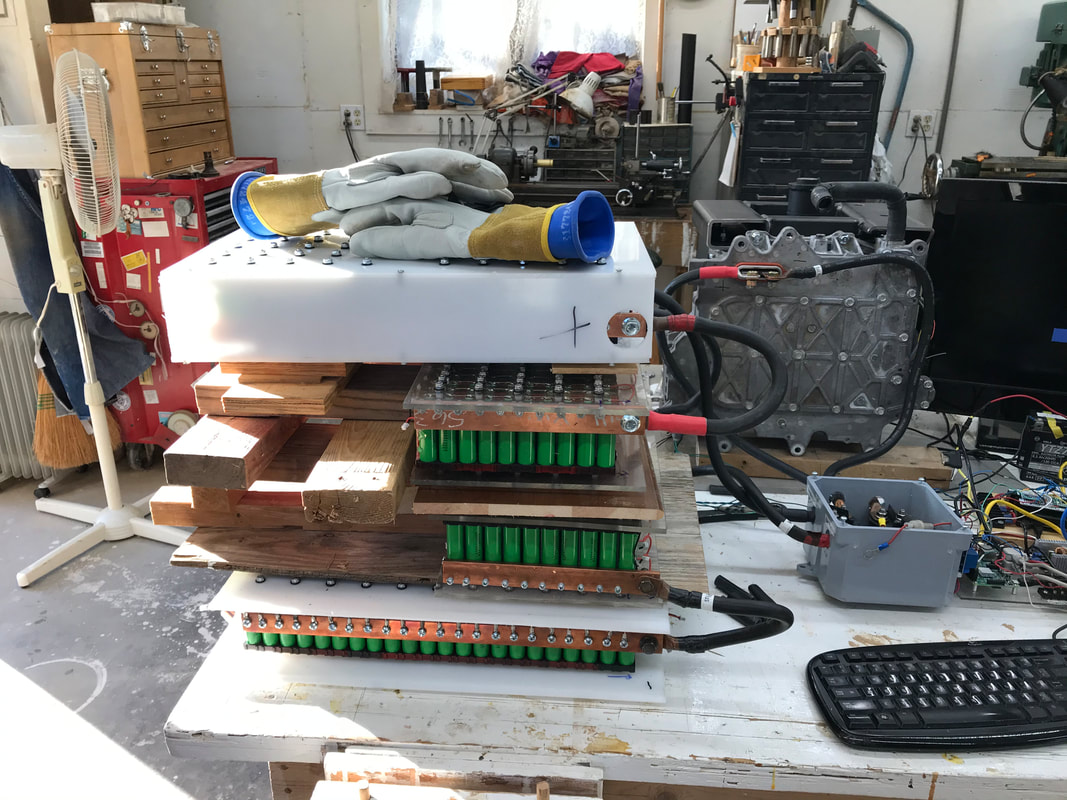

Hello Electrified Miata Fans! After a nearly a two week setback due to my mistake with a battery pack, we are ready to try mating the Miata transmission to Leaf motor #2. If we can get the transmission mounted and everything spins without vibration, what can stop us from making the car move? Please join us on this journey of blood, sweat, tears and recently fire. To make the car move, we'll need all batteries combined into a pack. The pack is only as good as it's weakest cell. One of the many BMS functions is to balance the cells in a pack, allowing all cells to be roughly the same voltage, giving us maximum range from our pack. Since this is a prototype, we'd like to have a 'control knob' on the balancing function. The lower settings on this knob will balance slower, but won't generate much heat. This control knob is implemented using Pulse Width Modulation (PWM) controlled by the BMS board firmware. PWM allows us to control the percentage of power we absorb when balancing is turned on during pack charging. Joe has been working to add this control knob to our boards. Most of my week was spent re-building the battery pack. This consisted of soldering the new cells, re-wiring the bus bars, drilling the new protective plastic covers and bolting everything together. My wrists and hands got sore with so much screwing around. Once this was done, I did a quick verification that motor control software would work when not connected to my home network. Verification took longer than intended when I realized my laptop's software wasn't in sync with the rest of the project. Once that was fixed, I packed everything in the truck including enough batteries to spin the motor over to Ed's shop. Motor #2 was at Ed's shop along with the transmission. I wondered if it would spin, as that had never been tested. After unloading the batteries , with Ed providing the physical test stand from scraps of wood laying around in the shop, we started connecting the batteries together in series to get enough voltage to spin the motor. Connecting the batteries was an ordeal for me. I vividly remembered connecting just the first lead, tightening the connection resulting in uncontrollable flames. My heart was racing as I tightened the these connections bolts. Luckily, we had time to take it slow, measure the connections, to verify no mistakes and no sparks. In addition, I could see the bus bars, which gave me more confidence I wasn't going to recreate that fire. The high voltage gloves used during battery connection are somewhat tricky to work it, since they are essentially two gloves, one rubber to protect from high voltage and a leather glove that protects the rubber from physical tears. Ed made the comment, "that must be like what the astronauts go through working on the space station". Ed also provided the baby powder that made working with those rubber gloves much better. I never realized how much my hands sweat, especially when nervous. After the pack was hooked up, Ed and I applied power and motor #2 came to life! Yeah!! I now have two Leaf motors that spin! The guys came over to Ed's shop on car night and everything was ready. First, we had to do a quick clean up on the welds to make the transmission mating surface flat. Then we placed the transmission on the bell-housing adapter but it would not set all the way down. After a few measurements and use of an industrial dental pick that Ed had, Brian determined the washer used as a spacer in the coupler was interfering on the transmission side. Bruce and Brian spent some quality time grinding with a Dremel, and the problem was ground away. We set the transmission on the motor. It sat well on the bell housing with only a minor warp-age from welding. It was certainly good enough to test with. The motor spun up, no wobbles/shakes/vibrations, very anti-climatic. I was stunned it worked so well. After a few minutes of realizing after all the troubles, we now had reached a major milestone, connecting motor and transmission, my eyes got moist with joy. Here are some technical details, for everyone reading. The motor wasn't even mounted down, but my previous experiments with a strapped down motor showed me using 5 newton meter (NM) to spin up and -0.5 NM. for stopping the motor would work just fine. 5 NM. translates to the number 10 in the CAN bus message since each increment is supposed to represent 1/2 NM. These levels of torque would avoid any sudden jarring and unconstrained motion. We thought we marked the bell-housing, but after we failed to find the marks when we took the transmission off, we realized we we had used a transfer punch without a sharp tip, probably the only one like that in Ed's shop. We re-installed the transmission and re-marked the bell-housing using a transfer punch with a sharp tip! Since we had to take the bell-housing adapter off the motor, we adjusted the flatness of the bell-housing using Ed's press. The drilling of the bell-housing went quick using a center drill, and thankfully the holes were less than 1/2", meaning they could be drilled relatively quickly. We mounted the transmission, and spun the combination to 5K RPMS as shown in the following video. Still no vibrations or shaking. It is time to mount the motor and transmission in the car!!!

In the next 2 weeks, priorities will be battery completions. This will include the side plastics for the re-built medium pack and end plastics to mount the BMS boards I'll also take a little time to organize the shop better. Too many open projects have created a lot of a mess. Maybe I can move one of the Leaf motors to the shed, since I know motor #2 runs too. Next week, we'll be taking a little time off to celebrate Thanksgiving. I am starting by being grateful for a Miata transmission mated to a Leaf motor. I'm also grateful for the great team I'm so lucky to work with consisting of Bill, Teresa, Sawyer, Bruce, Eric and Nolan Bitner, Ed Bailen, Doug Kimber, Joe Krosche, Scott Lambie, Ryan Brown and Brian Schlosser. Y'all rock. Thanks for all the *hard* work to get to this point. I won't be writing next week, but celebrating Thanksgiving instead. Look for the next update in two weeks. Hope y'all are staying healthy and having fun

1 Comment

|

AuthorBill likes cars that understand the 'go fast now' pedal. Archives

May 2022

Categories |

Proudly powered by Weebly

RSS Feed

RSS Feed