|

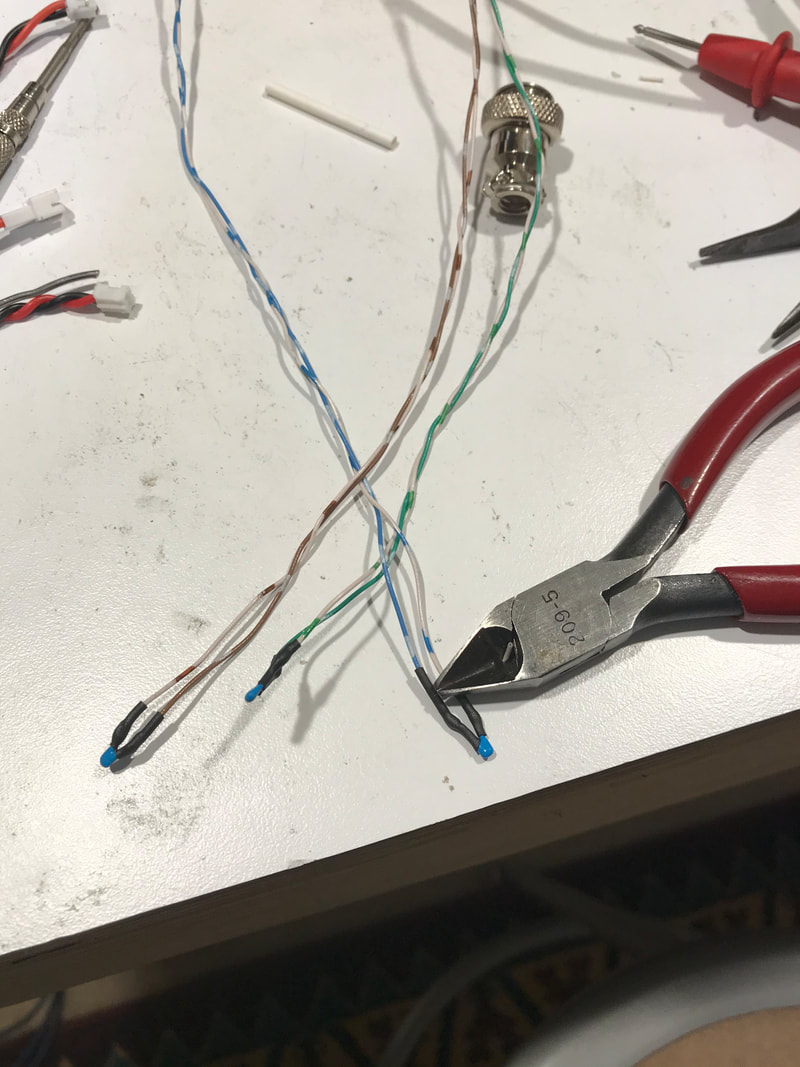

You know that feeling when you've done your best, but still didn't reach your goal? I'd worked really hard, taking care of the goals. We were finishing up the final item, ready to take the kart out under full power. I really wanted to feel the kart sprinting down the street. As we installed the power wiring, we periodically would make sure the main battery pack was still isolated from the go-kart frame. After addition of the most difficult to install wire, the isolation test failed. Surprised and disappointed, we worked to find the cause. Join us on the journey got go faster harnessing the power of electricity. The goals for last week were: 1. Order more connectors and replace the circuit board I destroyed. 2. Find out why one thermistor reading is not like the others. 3. Finish wiring. 4. Modify the user interface, specifically to add the BMS readings and to add a shutdown button, to cleanly shutdown the Pi's. 5. Test go-kart settings. Goal number 1 was easy, search the previous orders, verify the stock, and press a few buttons. Done! Loving software, goal number 4 was just begging for my attention. I found a bunch of details that were preventing the BMS code from working properly. This is the first time I've had multiple packs running so naturally, there were a few hidden problems there. There were also some configuration issues that prevented the voltage information from reaching the display. Once I fixed those, I could see both pack voltages on our display! I could charge the mini-pack and monitor the results on my phone! I was feeling a sense of accomplishment at seeing these pieces of the project come together. The first half of goal number 4 done! Now that the BMS was reporting, I wanted to add the temperature reading to our display. Adding temperature was more complicated than I thought. Have you ever heard of the Steinhart equations? I hadn't and it was an education. The thermistor devices we use change resistance when the temperature changes. Sounds pretty easy, right? Technical details to follow: Make the thermistor part of a voltage divider, supply a known reference voltage and measure with an Analog to Digital converter. This gives me a 10 bit number that represents the voltage in the voltage divider. Unfortunately, the thermistor devices are not linear, meaning the resistance doesn't change the same amount for a given change in temperature. The non-linearity requires some math to give correct reading. Luckily, the Internet to the rescue and I found code that accomplishes the non-linear conversion. After dealing with Kelvin to Celsius, I was nearly set. My son Sawyer helped with the algebra needed to convert the 10 bit digital number representing voltage back to the resistance of the thermistor. End of technical details. Now I could display both the motor and controller temperature on our display. Dave Evans has expressed interest in purchasing the motor and controller, which means I should pay careful attention to these components not to melt them in a blaze of excitement. We can put warnings on the screen if these components are getting hot. Heck, we could even stop the kart if things get too hot. With the temperature under control, it was time to tackle goal number 2, finding out why a battery thermistor appeared to be giving reading that didn't correlate with the temperature. Checking the data, the problem was was with the thermistor that measured temperature in the middle of the pack. The thermistor with the brown leads is was damaged during installation? I replaced the device with a new one and everything was working. Goal number 2 done!

I still needed to finish up goal number 4, adding a shutdown button. That took some skull sweat on my part. Ideally, each Pi would shutdown, in a particular sequence to avoid random behaviors with the contactors and errors on the user interface. After some experimentation and research into how to transfer 'admin privileges' to shutdown the Pi's, I got everything to work. Goal number 4 finished before car night! Bruce, Brian and Joe came over and prepared the kart for it's first test. They wrapped and strapped all the signal wires. Joe labeled the connections so we'd know where each connector went if we had to take it apart, or something came apart by accident. Then we started on the main power connections. The pack was not designed for 2 connections on one bus bar, so space for the wires became quite tight. We started on the toughest connections first and Brian got everything connected. Since the connections were tight and very close to the frame, we slipped a piece of 3/4" heater hose to insulate the wires from the metal frame. The main pack is meant to be insulated from the frame. This becomes extremely important when dealing with the 400 volts of the Leaf motor. With the negative wire attached, I did a spot check using a meter to measure between the unattached positive bus bar and the frame. We saw voltage, meaning the frame wasn't isolated like it should be. After much debate and testing various components and visual inspection, we found that the rubber heater hose is a poor insulator. Rubber is normally a very good insulator, but the automotive grade heater hose is not. We'd spent most of car night looking for where the insulation was broken, so we'll have to test the Kart next week. In other news, Ryan Brown let me know "I wish I had better news but I have not been focused on the Miata project. With life moving around me, this has been put on the back burner and my priorities are shifting. I am still an active follower but I don't have the time to be a developer." Ryan's area of contribution to our project was to be software documentation. This means we'll be looking for someone who can read/understand python and enjoys generating documents describing the operation of code. If you know anyone, let us know by contacting me or any member of our team. Our goals for next week are: 1. Test go-kart 2. Clean up shop. 3. Move Miata back to my garage. 4. Start on battery balancing code when charging the go-kart. As always, thanks for reading. Remember, heater hose is not an insulator!

0 Comments

Leave a Reply. |

AuthorBill likes cars that understand the 'go fast now' pedal. Archives

May 2022

Categories |

Proudly powered by Weebly

RSS Feed

RSS Feed