|

. Hey Electrified Miata team, here's the latest update! For those of you following along, last week, the goal was get the kart software published on GitLab and to get a second battery pack operational. The second pack will be used for higher voltage test with the Leaf motor! Publishing the software will allow us to share the software within the group so everyone can find bugs and improve the code. I strongly prefer to publish code that functions correctly, but in this case, I made an exception so I could receive help from the rest of the team. With a 'shelter in place' order in force, we have to work remotely so publishing the software became a top priority. Luckily, publishing software via Gitlab is a fairly easy thing to do. Before publishing, I spent a few hours on the necessary evil of code clean up. The five minutes of code check in and publishing was a comparatively quick. I needed some help with our display code. I've never done more than a surface learning of HTML and JavaScript and now it shows... I could spend my time studying HTML and JavaScript OR I could ask our team for help. I did as much as I could and was able to get the web page to update with kart events, like turning a switch on. I could also receive events initiated from the web page, like turn the headlight off/on, but I certainly couldn't make the web page look anything like I wanted. Lucky for us, we have Brian who knows how to do this kind of thing. Publishing and sharing the code also promotes learning, which is something I particularly enjoy. I've been using the programming language, Python for nearly 20 years and still love using it. Joe had already published his BMS code. By studying Joe's test BMS code showed me that a python feature called 'decorators' can have lots of uses besides the code profiling I've used it for. I loved learning about new uses for code features and can see the 'decorators' being useful in the future. Thanks to both Joe and Brian! With code issues being taking care of, I could turn my attention to building the second battery pack. Building the second battery is both easier and harder than the first. I learned some lessons with the first pack, so that makes building the second pack easier. Now that I know the outcome of constructing a pack, the second pack isn't near as exciting. The task is fairly repetitive, good for a machine, but boring for the human. I didn't modify my tools this time with unexpected arc welding. A pack build consists of many steps. For those following along and possibly wishing to build their own, here are the steps:

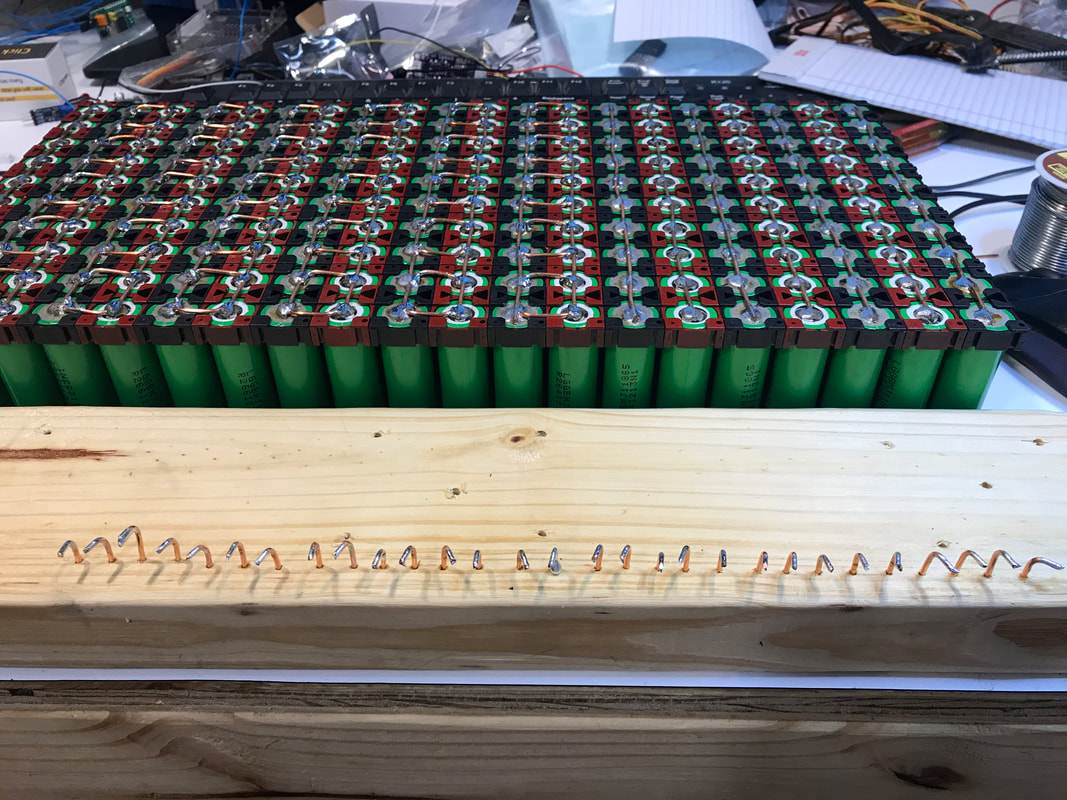

Brian called via Slack on car-night to discuss and debug the display software. Mildly annoying, we couldn't share his screen, because that functionality is only included in the premium version of Slack. We used verbal communication over slack to discuss what our respective screens said and were able to debug. Brian will continue to work on the display software. Joe finished installing the processor to the BMS 20 boards. He's discovered several anomalies, due to the hardware designer making changes and a few mistakes. Joe will correct these and start working on software that works better for our situation rather than the original design. This pushes us towards developing our own BMS design. Thanks again to Stuart Pittaway and his DIYBMS4V making this BMS board project open source. The goal next week is to finish the second battery pack and attempt to get one of our Leaf motor spinning. If successful, then we'll need battery packs 3 & 4, since my power supply can only supply very limited amounts of current. A limited amount of current means very limited acceleration tests. However, we'll be able to verify 80 percent of the motor software. If we fail to make it spin, I'll need to read the the diagnostic codes from the inverter. I'm starting to read the E-book http://opengarages.org/handbook/ebook/ and hoping learn how I can get the diagnostic codes from the inverter as well as being able to interface to a cars existing system. P.S. I didn't take a lot of pictures this week. Here is one with the battery under construction. This is part way through step #4. The wires in the 2 x 4 are prepped to be installed. I'll take more pictures for next week.

0 Comments

Leave a Reply. |

AuthorBill likes cars that understand the 'go fast now' pedal. Archives

May 2022

Categories |

Proudly powered by Weebly

RSS Feed

RSS Feed