|

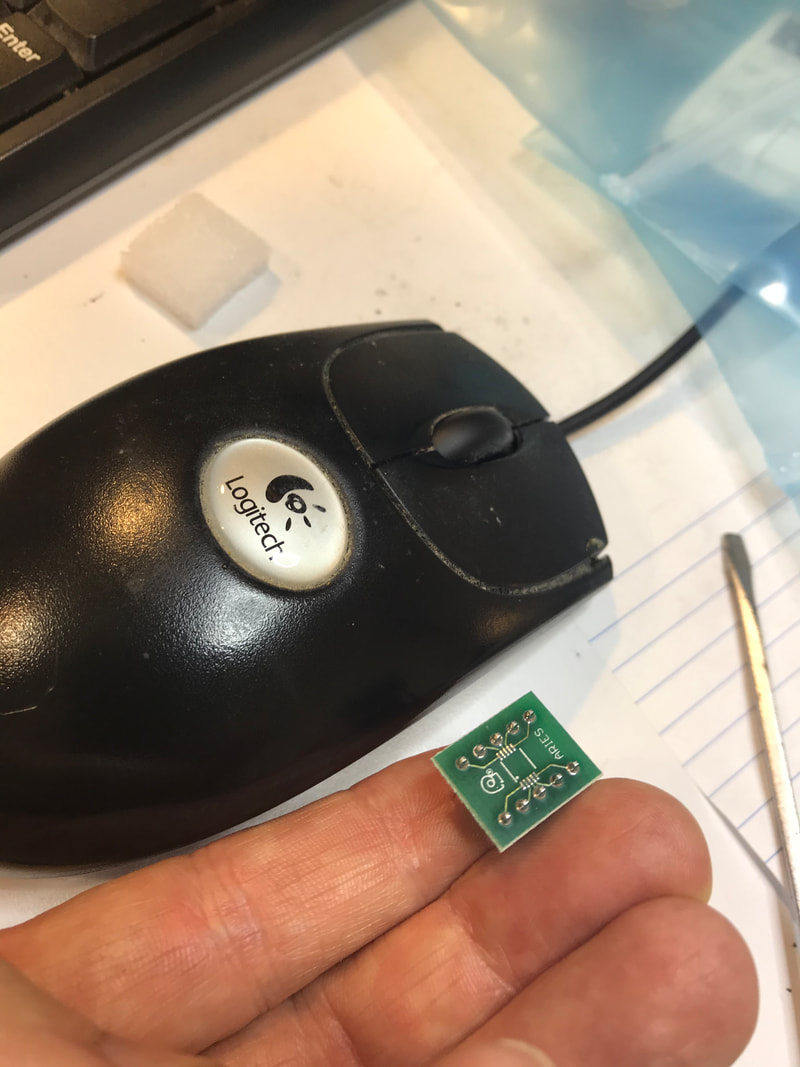

Hello Electrified Miata and Electrified Formula-Mazda fans! This is your weekly update on putting smiles on faces through the magic of magnetism and electricity. I was blessed with three beautiful blue Miatas in my driveway this Sunday. They have brought knowledge, parts, donations and lots of goodwill to the Electrified Miata project. In return, I wanted them to experience the go-kart we've been using for testing the Miata batteries. While the go-kart is not particularly good at cornering, due to old tires and center of gravity being too far back, it *is* a fair amount of fun. Austin Waffle likes to drift with his turbo-charged blue Miata, so naturally he tried drifting with the kart. Being a prototype, it has a few problems one of which is where the throttle gets out of adjustment and stuck open. Austin handled that with complete calm. "Hey, this thing still wants to go". After sorting that out, we watched Austin do a beautifully tight 720 degree rotation. A friend of Austin's, Josh, a new Miata owner tried the kart as well. Smiles all around.. Josh and Austin helped me diagnose problems with the Electrified Miata's roof latches not wanting to stay shut and offered various solutions to the problem. Thanks guys for the help, parts and smiles! BMS update: You may recall last week Joe had made tremendous progress on the next revision of the BMS board, where we need to update the processor. The only glaring problem was not be able achieve the low power mode. Since the BMS boards are always connected to the battery, using as little power as possible is extremely important! Joe methodically diagnosed the problem and got to the point in micro-amps where he couldn't measure the power being used! Success. Anyone care to donate better test equipment? The next steps will be to re-work the board to use this newer processor. Joe will have to account for all the pin movements, filters on the analog inputs, and having the connectors mounted on the bottom. This should be the last round of revisions for a cheaper, expandable BMS system. Thank you Joe for sticking with it, despite the many challenges. While Joe was busy trying to measure micro-amps, I just wanted to remember what time it was. No, I'm not that old, but without power, the raspberry Pi's don't know time it is either. I received my Real Time Clock (RTC) module from DigiKey and installed it. With addition of this one magic line 'dtoverlay=i2c-rtc,ds3231' in /boot/config.txt, that Pi was happy to use the RTC and keep track of time. Now to figure out how I can add this to my current set of Pi's. Plus configuring the other Pi's to get their time from the single Pi that has the RTC installed. I booted our Pi Pico board, which will be used for hard real time tasks. The first task will be to measure the speed of the transmission output shaft. We'll need to interface to the speed sensor in the transmission using this chip. My heart sank when I saw the size of this thing. How the heck would that be soldered to that board? Lucky for me, others on the team are much more experienced than I and took on the challenge. Joe, with his superpower sight and steady hands, was able to solder this with out a re-flow oven, which is normally used for this type of work. Thank you Joe! With all these problem solved, I'll have to get back to the basics and work on the battery cover next week. Wish me luck on not destroying any more battery cells. Our second project, the Electrified Formula-Mazda made excellent progress as well this week. You may have noticed that there were three cars at my house to drive the go-kart, but I only mentioned two people. Arm Suwararnaratana has that beautiful blue 5-1-2 (yes, it rhymes) Miata and came to offer his welding services. He also has a plasma cutter! As the number of projects have doubled by adding the Electrified Formula Mazda, we can use talented people like Arm! Welcome to the team Arm! Car night arrived, and Dave, Broch and Arm had already done some preparation by having the welder and it's attendant gear, like the gas bottle, extension cords and welding helmet already there. We had two items to accomplish that night. 1. get the front 'engine' mount plate drilled and placed. 2. weld an extension onto the 'horseshoe' motor/trans-axle adapter to pick up one more bolt on the trans-axle mount. When Brian saw my mini drill press, he figured that the 1/2 hour round trip to is house where he had a full size drill press was worth our time. We marked the plate with a bolt and well placed paint and Brian left us to get the plate drilled. While Brian was gone, Arm fired up the welder, cleaned the steel and tacked the extension piece in place. Bruce cut the previous tack welding apart and we proceeded to look at ways of optimizing or simplifying the frame attachment. Brian returned, with the plate nicely drilled, did a bit of filing on two (of the 4) holes and setup the mount to accept the 1" x 2" square tubing we'll be attaching the plate and horseshoe. Arm tacked those into place. Awesome progress. Thanks to Arm, Brian and Bruce for getting this done and thanks to Dave, Broch and Arm for having everything ready.

Next week, I'll work on the getting the Electrified Miata large battery plastic cover drilled on both sides. On the Electrified Formula Mazda, we'll also be finishing the prototype motor mount assembly. I won't be writing to y'all next week due to celebrating Easter and my editor (*Wife's*) birthday. As always, thanks for reading and hope y'all are having fun and staying safe.

0 Comments

Leave a Reply. |

AuthorBill likes cars that understand the 'go fast now' pedal. Archives

May 2022

Categories |

Proudly powered by Weebly

RSS Feed

RSS Feed