|

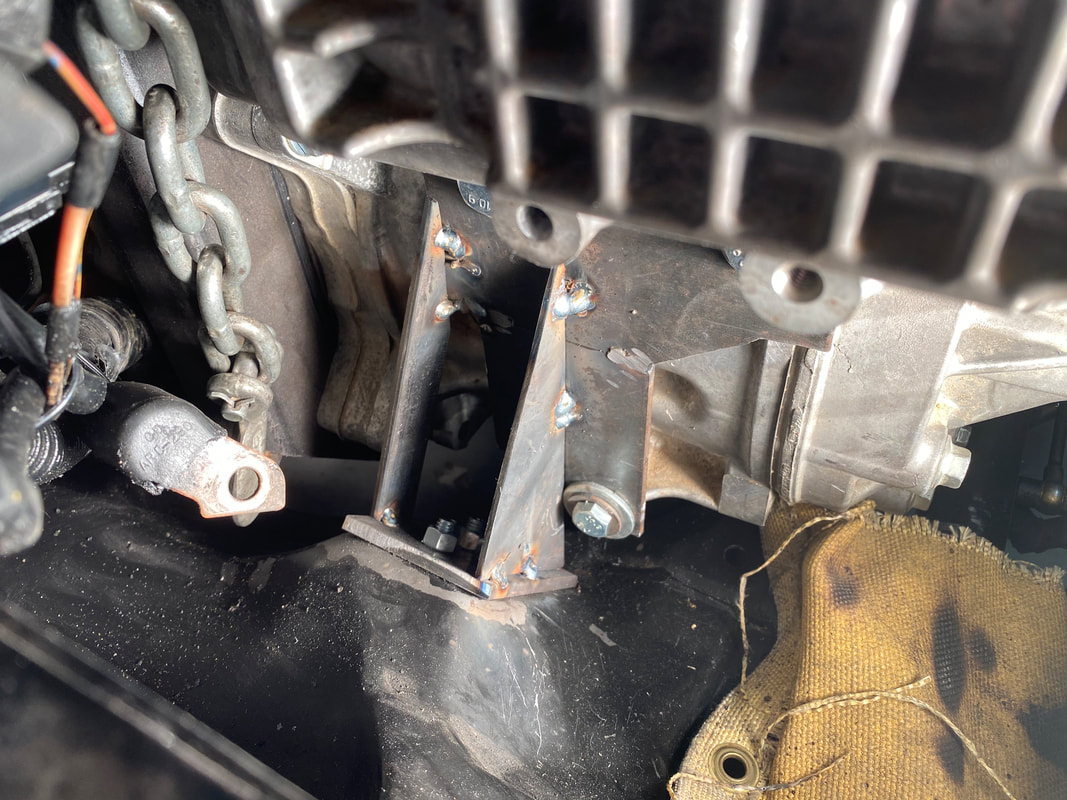

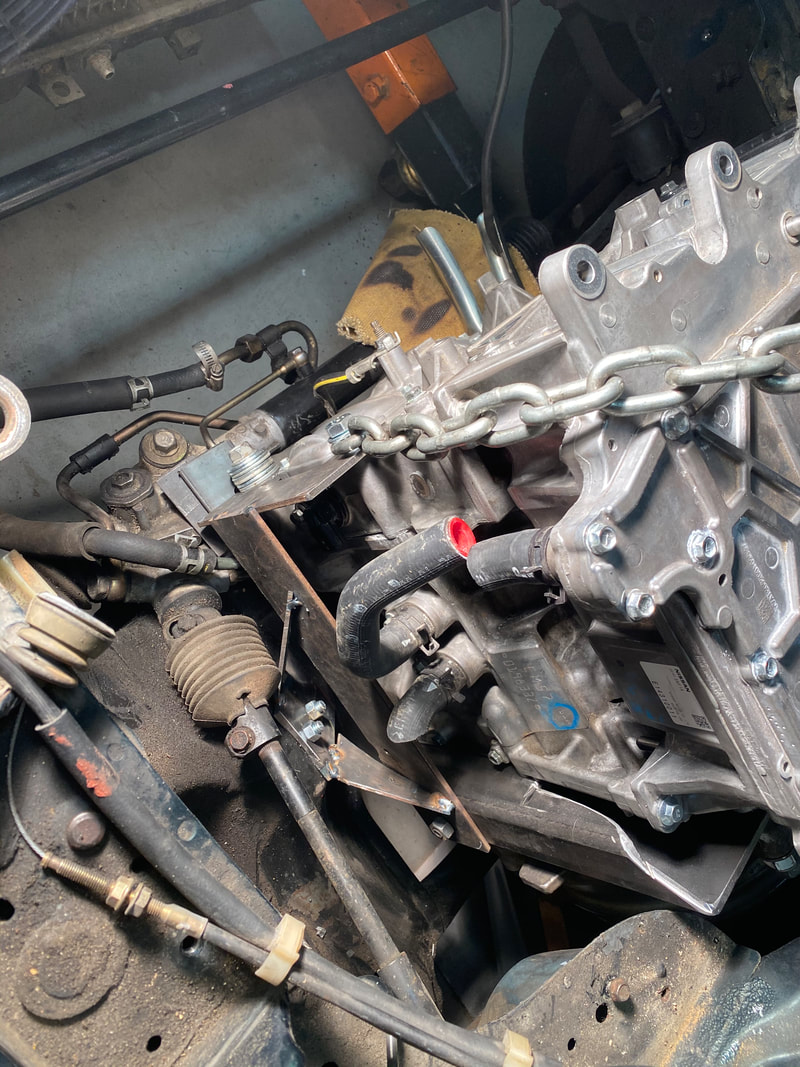

Hello Electrified Miata Fans. This week, we split up into three different teams to divide up the work. Bruce and Eric worked on welding the motor mounts. Brian and Dave are fitting the Pi's and supporting electronics in boxes we can mount to both the go-kart and the Miata. I'm working on making the software components work together. Ed and Joe have the week off waiting for the rest of us to finish, lol. Join us on the journey to make an Electrified Miata. Bruce and Eric are handling the metal working aspects of this project. This week, the motor mounts were designed, constructed and tack welded in place. Here are the passenger and drivers side motor mounts Eric has been doing a lot of the metal cutting. The next step is to figure out how the batteries in the front will be mounted. This will be done now so that we can insure the battery mounts won't interfere with removing or installing the motor. After that, they will finish the motor mount welds and start work on the rear of the car, replacing bushings and fixing the stock brace mount which broke during removal. Having team members that can weld solves a lot of problems! Awesome job Bruce and Eric! Would you like to play Tetris with 3 Raspberry Pi's, complete with daughter boards and BMS serial isolators, 2 power supplies, 1 network switch and the partridge in a pear tree? Here, Dave and Brian are doing this on car night. This picture reminds me of the scene in Apollo 13 where all the parts are dumped out on the table, and the engineers have to figure out how to make it work. Dave shortened the mini battery pack by 5 mm so it would fit just right in one of the boxes. Brian figured out where the Pi's, power regulators, and network switch would go and how to mount each of them. The Pi's will be mounted to a small bit of plastic which will be cut to size for the enclosing box. I've received my instructions from the engineers and will make it work. A big thank you to Dave and Brian for solving Tetris as I'm not very talented in spatial problems.

I've been working on integrating our software into one system. The BMS software system has minimum functionality and more work is needed to read external temperatures. Each BMS board can read both the board temp and and external temp sensor if equipped. We'd like to know if anything like motors, controllers, or batteries are getting too hot! Brian and I tested our display system months ago, but now it's time to use it. Connecting all these sub-systems together will require joining multiple software systems. The infrastructure worked in theory, but when I tried to configure it for the go-kart, I found some software routing details were not finished. I'll be focusing on this to put the whole system together. Going forward, we need to get the battery packs finished before we can install them in the car. Finishing the battery packs is mainly dependent on finishing the plastics and having enough BMS boards. Getting more BMS boards is dependent on proving the design is solid in all the ways we need, which means running a few charging cycles and lots of testing. We'll be using the go-kart to test our two small Miata packs. This will allow us to exercise both the BMS hardware and parts of the eMiata software. Once this is done, Joe will generate the next revision of the BMS boards and get enough boards to finish the car. I look forward testing on the go-kart. Wonder how soon I'll need new tires? Such hard work ahead, discharging kilowatts of power on the pavement, lol. Thanks for reading! Hope y'all are staying safe and having fun!

1 Comment

|

AuthorBill likes cars that understand the 'go fast now' pedal. Archives

May 2022

Categories |

Proudly powered by Weebly

RSS Feed

RSS Feed