|

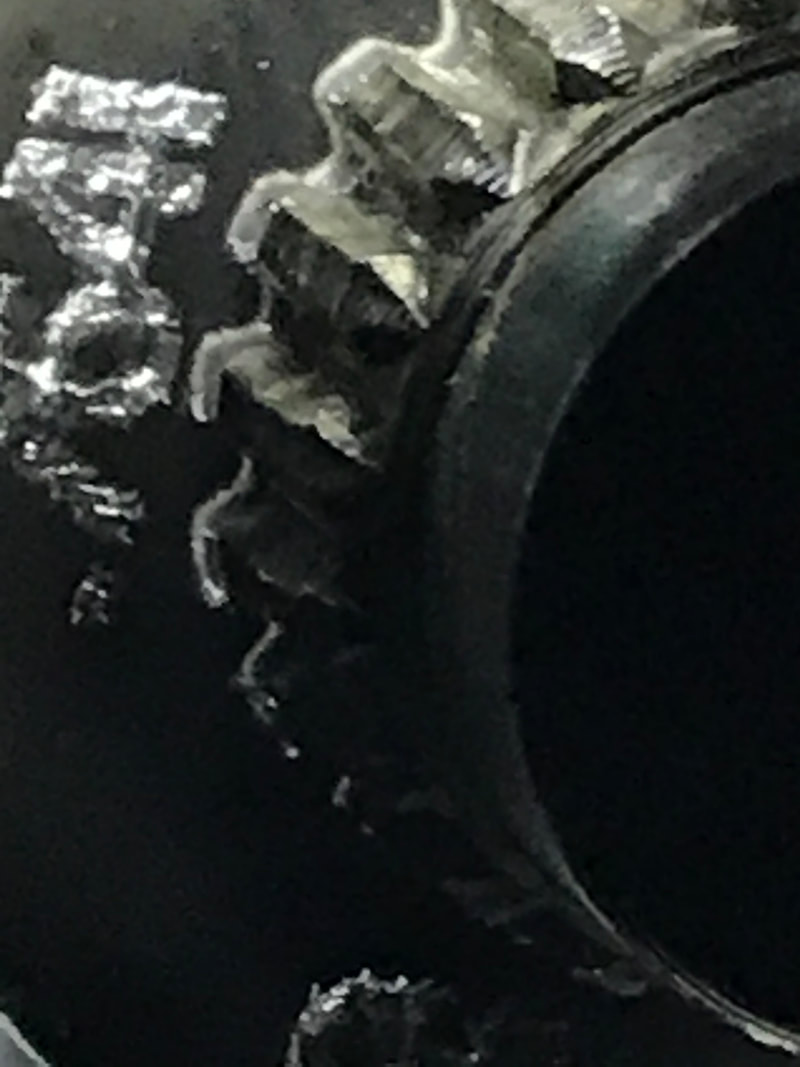

Here's a not so quick update on the Electrified Miata! As I was reading over my notes from last weeks activities, I was struck by the number of people that are helping make this project progress from dreams to reality. These people span the range from complete strangers to my dad, brother, son and wife and many people in between. I'm humbled and grateful that so many have chosen to participate in making this dream come true. Anybody that wishes to support the project can do so by purchasing some used parts from me. I'm sure there is a big crowd out there needing a 1999 stock Miata tape deck, complete with a tape called 'Demon Sweat'. Wait, you're are selling a cassette deck? Have your lost your mind? The big news is I found a parts car! Last week, the plan was to do some clean up, reducing the number of Pi's from 4 to 2, and start looking for a Miata. In addition, adding real time graphing to the system so I could do some fancy cruise control, ie. PID tuning. I started to get micro-focused on getting a parts car so I could measure where all the batteries would go. As my wife can tell you, once I start with an idea, I can kind of get obsessed. My wife would remove the the 'kind of' from the previous sentence. There are two main sources of parts I need, a wrecking yard, and individuals selling parts from their projects. I wanted a relatively complete car, with cheap being the main quality. I investigated getting a car that had been wrecked, since wrecked cars are usually cheap and the team can fix lots of things. I called a used car dealer whom I trusted and asked him how much it would cost to pick up a wrecked Miata. The transportation costs ranged from $140 to $240 depending on car location. Then he would charge me an additional 300$ for his dealer fees and title work and expertise on how much a wrecked car should cost. All I could see was ~$500 spent in fees that were not parts. These fees would be quite reasonable if I was picking out cars worth $10K or more. However, for the first prototype I want something I won't feel bad if it comes out like looking like Frankenstein, that is I want something cheap, like $1000! I looked up the cost of hitches and renting car dollies. For $250, I could get a car home assuming my truck could tow it and I would have the hitch in case the prototype car ever broke down. I decided to get a hitch and put it on the truck. That took a couple hours as many of the hitches are complete bolt-ons, leaving me plenty of time to start looking online through the 200 older Miata's for sale. I found what I was looking for and the price was right! I was so excited that I was dancing around the house and grinning from ear to ear. I actually felt giddy with excitement. Apparently, I really missed my previous Pantera project and NEEDED a new project. My wife told me I was acting like a six year old. (Big Grin) Now I had to get the Miata home. I turned to my brother for help with this task and we went to New Branfuels to pick up this 1999 Miata with a wrecked engine. Three man power and one driver was enough to get the car on the dolly. Brakes seemed to work stopping the car at the top of the dolly. You never now what you'll be getting when the car doesn't run, but even if half the parts were bad, it will still be better financially than trying to get everything from a junk yard. Plus I might be able to sell a few parts, such as the motor and exhaust since I certainly don't need those for electric version of this car. What good is an oxygen sensor for an electric car? Thanks to the previous owner Sky, for selling me this car and being open, honest and easy to make a deal with. Thanks to my brother Bruce for being there to help out on yet another crazy project. I dream up an idea and he's been able to turn those ideas into reality, time and time again. A little rear brake drag is the most trouble we encountered on the trip home. Time to celebrate with a little bit of Scotch.. The battery on the project Miata was fully drained (measured 0.7 volts, should be 12 volts). My high capacity battery charger refused to charge it. Teresa mentioned checking the battery cells and they had water in them. I put a motorcycle charger on it, which didn't have all the smarts in it to determine the battery was dead. Surprise, surprise, after a few hours the battery started to take a charge! I able to put the big battery charger on it and bring the battery back to life. Now I could turn the car on and find out it had 221K miles on the clock before it threw a rod through the oil pan. The next challenge was to move the car around. I remembered my 1976 Ford Pinto with a manual, that I could still move using the starter motor when I drove it into water that was too deep. 1976 was a time before all the safety equipment prevented people from doing that. Bypassing the modern safeties, I could move my car around with just the starter motor, although it does sound more like a train with the broken rod pounding out the beat. My first all electric ride, ahhhhhh Brian remarked "Needs more train horn" lol. Thanks for Sawyer for recording the first all electric trip. I joined the Miata group of Austin on Facebook and posted my find and project. Eleana, a member of that group, told me she has a car from the north and needed a full exhaust system. It took a me full 12 hour day to remove the parts. Now I have a much better idea of how to do this. Despite being a southern car, after 20 years and 221 thousand miles, some of the parts had rusted together. Lots of WD-40, a some four letter words, the impact wrench and help from my son Sawyer got all the pieces off. What a dirty job. It was made a little easier when I realized I didn't have to put any of the pieces back and could use the angle grinder to cut off the exhaust hangers. Thanks to Eleana Garrison for making a great donation to the project and getting the parts out of my shop. With the exhaust gone, I could start measuring for batteries! I'll admit to being rather 'fixated' on the batteries being in the center of the car and down low after driving a Tesla P100D. The 2018 Tesla weighs in at nearly 5000 pounds and yet was achieving .92 gees around a skid pad. It didn't feel that heavy while driving it, except for trying to slow down in a hurry. Center of gravity appears to be important to make a car handle. The 'frame rail', under the car, which I crushed with a jack not knowing that those are NOT jacking points, extends down 1.75". This is not enough to let me stand my batteries in the vertical position. I could lay the batteries horizontally, but then can't fit enough of them to fully power the car. Miata's are known for their ability to corner as well as being light weight. I want to enhance pr equal both of those features. After spending some quality time with the measuring tape and a calculator, I reached the conclusion that I'd have to cut the floor boards if I wanted to put the batteries in the center of the car. This is exactly why I wanted a parts car. I can experiment without regrets as I know not all of my ideas turn out well the first time. We will see how the cutting of floorboards works out. With the Leaf motor running well, we need to be able to couple that motor to the Miata transmission. Doug Kimber updated the CAD drawing of the coupler and cut out the new version in plastic. I received the piece this week, painted it, installed it and took pictures. Here's a 8X closeup. It looks good so now we have to figure out how to make it in steel. After all that physical work, I was more than ready to sit down and do some programming.

I want to play music with my Leaf motor. That might sound like an odd statement but it's actually a stepping stone to making the car faster. Geek mode on: I should be able to play a tune if I can make 1) the Leaf motor stay at a particular RPM using torque commands and 2). make the motor transitions between speeds quickly. I consulted with my nephew Nolan, the family genius at Rice Univerisity and he reminded me that RPMs are just frequencies divided by 60 (minutes to seconds). From Wikipedia, the note 'A4' found in the center of a piano keyboard has the frequency of 440Hz, and each successive pitch is derived by multiplying (ascending) or dividing (descending) the previous by the twelfth root of two (approximately 1.059463). For the Leaf motor to play an A4, it would have to spin at 26400 RPMs. So my Leaf motor will be playing lower notes only. At 10K RPMs, the motor would be close to E3. End Geek Mode: Control of the motor RPMS and transitioning to a new desired speed is accomplished with PID software, which is very similar to how cruise control works. To see and measure the effects of the three different adjustment factors for PID, I need real time graphing to work. That turned out to be easier than I thought and I didn't need to get dirty doing it! I love software! The practical use for PID in a car will be when changing gears without a clutch. The stock 1.8L motor and gears allows the Miata to go ~35 mph in first gear at 7000 rpms. Using a Leaf motor, the same setup should be good for about 50 mph in first gear. This means I'll have to shift to reach 60 mph. Shifting without a clutch can be slow because the motor RPMS have to match the next gear fairly close before it will slip into gear not to mention wear on the transmission synchronizers. The faster I can make the motor RPMS match the next gear, the faster I'll be able to shift gears and get some good 0-60 times, even with a single motor. In other news, Joe has completed the infrastructure for the BMS2.0 boards and can start implementing the features, like voltage and temperature measurements and also current shunting used to balance all the cells. This is a major milestone for the project. With a solid infrastructure in place, this provides more stability in both the code and the end results, ie protecting the batteries. This is great timing, since I'll be running the motors more and more and will have need to automatically monitor the pack cells, especially the mini-pack. Thank you Joe for tackling some of the hard stuff. This weeks news wouldn't be complete without mentioning my dear wife Teresa, whose car gets put out of the garage when I need to work on the Miata. I couldn't do this project without her support, her editing, listening. And she tops it off with smiles and appropriate ohhhs and ahhhs when things happen in this project. Thank you again Teresa! Next week goals are cleanup. We are moving from the initial prototype to an advanced prototype. Both the hardware and software needs a bunch of clean-up. Specifically, I'd like to reduce the number of Pi's from 4 to 2. On the software side, I need to automate the startup and shutdown procedures as well as get some standardized logging built in. Thanks for reading, and stay healthy!

0 Comments

Leave a Reply. |

AuthorBill likes cars that understand the 'go fast now' pedal. Archives

May 2022

Categories |

Proudly powered by Weebly

RSS Feed

RSS Feed