|

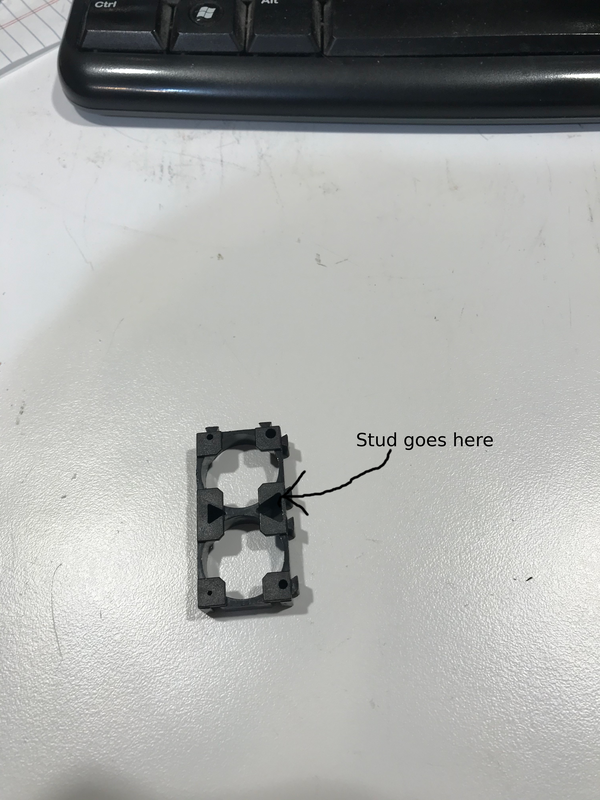

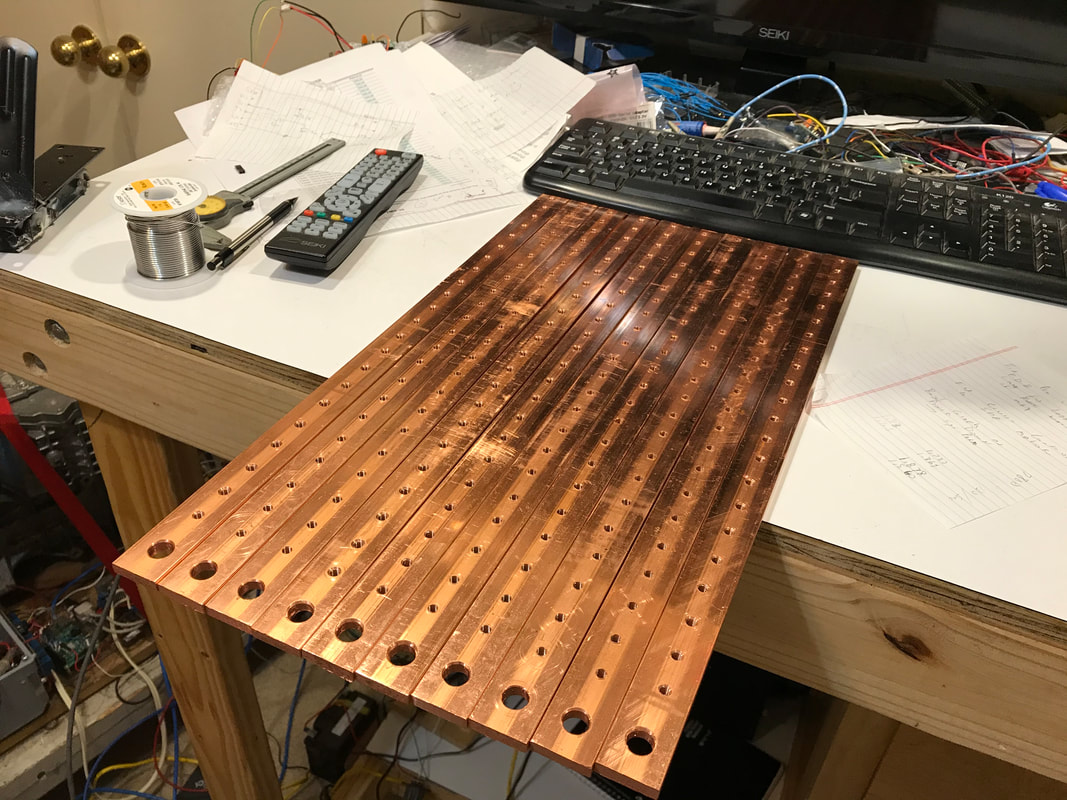

Hello Electrified Miata fans. The coupler is coming! The coupler is coming!! The mentioned coupler is the piece of steel that goes on the Leaf motor shaft and provide us a place to weld the clutch splines from the Miata, allowing us to join the Leaf motor and Miata transmission. Since it's a custom design, there is some doubt if it will work the first time. A lot of other sub-projects depend on the coupler, so having it arrive nearly one week earlier than the one month estimate is great. Last week's goals were to continue assembling the batteries, finish drilling and tapping the battery bus bars and build 'mock up' battery boxes. We'll also do more software cleanup and testing with the multi-hub feature. For battery assembly, we found a different design than the packs that currently are used for bench testing and the go-kart. When assembling 704 cells, it was significantly faster to assemble the 4x6 cell panels than the 1x2 cell panels. However, drilling the correct holes for the supporting studs requires a different process. With the 1x2 sections, the drill bit was wedged in the corner. The 4x6 design requires a different method to locate where to drill, since the area is much larger and we'll use the same drill size. A transfer punch does the job nicely, but being too aggressive with the punch will remove the entire center section, which is *not* desired. We did finish solder bumping the large pack and have one side connected in parallel. The two smaller packs are also assembled. Ten bus bars are cut, drilled, and tapped. All 10 of the bars add 14.1 lbs to the entire pack weight. Have you ever tapped a new hole for a screw? Typically, this is done by hand but neither Ed or I were looking forward doing 220 holes by hand. YouTube to the rescue! Someone was using a hand drill to tap copper bus, 1/4" thick, the same material we had. Ed had 10 taps on hand and was willing to experiment in hopes of something easier than hand tapping 220 holes. I experimented and got the hand drill technique to work without breaking a tap, which is what usually happens. A drill actually had a minor advantage of the tap slipping in the drill chuck as the torque got to be a little higher. I learned to manage the speed vs torque and could tap holes fairly fast by the last hole. Thanks Ed for all the help and use of your well stocked shop! The battery boxes have be mocked up using the wood and plastic that Ed cut. The boxes have be delivered to Bruce who is planning the metal work needed to mount the batteries in the car. Bruce has already calculated the steel required, made some decisions about material sizes and provided an estimate on cost. We'll be ordering some steel soon! Thanks Bruce for bringing your metal fabrication skills to this project. We also acquired a used laptop to support the car on its first voyages until all the software is fully tested. The laptop has a few dead pixels, shown by the white spots and well used battery but seems to run OK. Linux has been successfully installed and much of the required software loaded. I still need to test the battery, which showed poor health while running Microsoft. If indeed bad, I'll need to repair/replace it. I do have a few batteries left over from the Miata that could work in a laptop if needed!

We continued to improve the system software and the multi-hub feature is running successfully under ideal conditions. Now we upgrade the Leaf-motor project to use the multi-hub feature and make any adjustments needed for less than ideal conditions. Next weeks goals will be evaluating the new coupler. Depending on the result of that, I'll either be planning to pull the motor/transmission, or I'll be working with Ed and Doug, to revise the drawing and get a updated version quoted and ordered. We'll also work on more battery assembly, and getting the multi-hub software working on the Leaf project. Hope you're staying healthy and having fun! Thanks for reading. I've been having fun chatting with people about this project.

0 Comments

Leave a Reply. |

AuthorBill likes cars that understand the 'go fast now' pedal. Archives

May 2022

Categories |

Proudly powered by Weebly

RSS Feed

RSS Feed