|

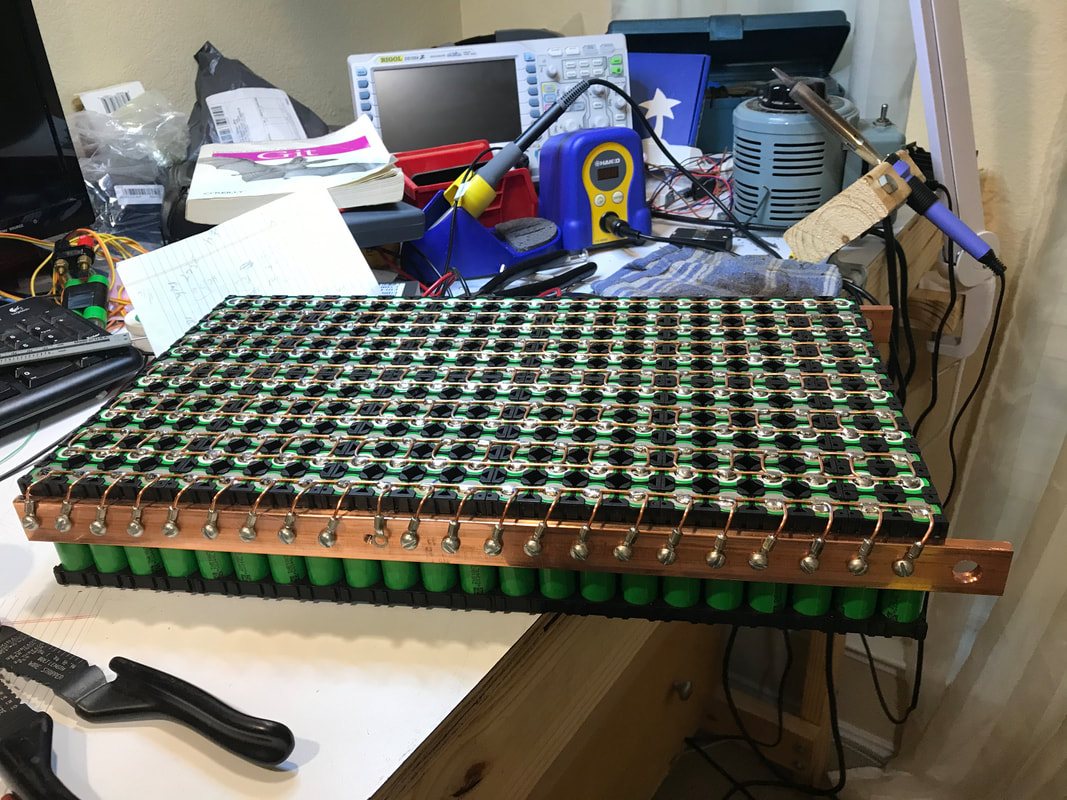

Hi Electrified Miata Fans! Here's a very short update. One smaller battery pack partially assembled. I'm doing some research to see how I'd speed up battery production. No definite conclusions yet, but laser welding looks to be the most controlled for copper sheeting. The smaller packs are so much faster to assemble than the large pack!

The next steps for battery assembly are to make grooves in the plastic tops and bottoms. This will allow us to install plastic side protectors and seals. We don't want road debris and direct moisture in the pack. Once the two smaller packs are complete, we will test them on our go-kart. We will need a bit of fun after all this construction. No pack will be complete without the BMS connections and boards. Joe is completing the BMS board assembly and has already assembled 10 boards. The test fixture boards, which will install firmware and verify functionality has been ordered and are awaiting partial assembly This means they should ship sometime next week if all goes according to plan. Thanks Joe for continuing to make progress. Ryan Brown, another Miata owner, met last weekend so he see the car and get a raspberry Pi to start documenting our code and how it works. Having a test environment and being able to experiment is essential to good documentation. It was nice to meet in persons after chatting on the phone. Thanks Ryan for helping out. I look forward to seeing your questions and comments on our code. I won't be writing to y'all next week as I'll be taking the weekend off for some R&R. The goals remain the same, complete battery packs. Since everything will be nearly the same, as this week, I'll save you from the monotony! Hope y'all are having fun and staying healthy! Please comment if you have idea on how to speed up battery pack construction. Thank you for reading and commenting. It makes a positive difference!

0 Comments

Leave a Reply. |

AuthorBill likes cars that understand the 'go fast now' pedal. Archives

May 2022

Categories |

Proudly powered by Weebly

RSS Feed

RSS Feed