|

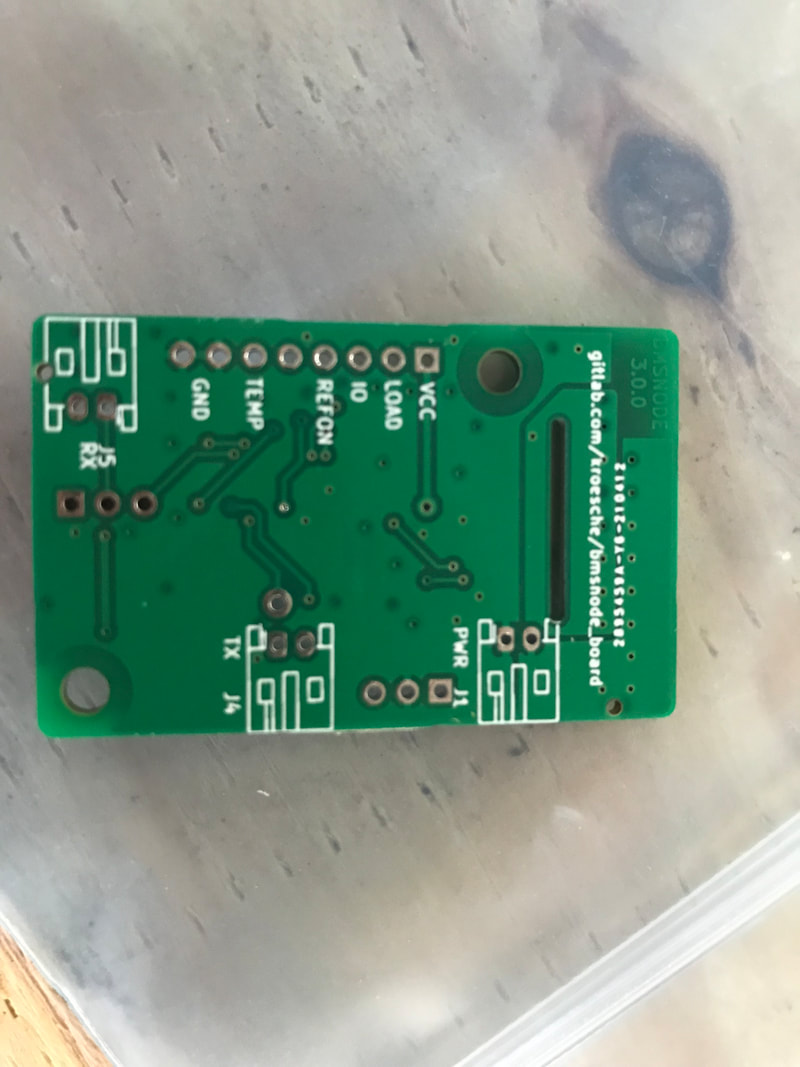

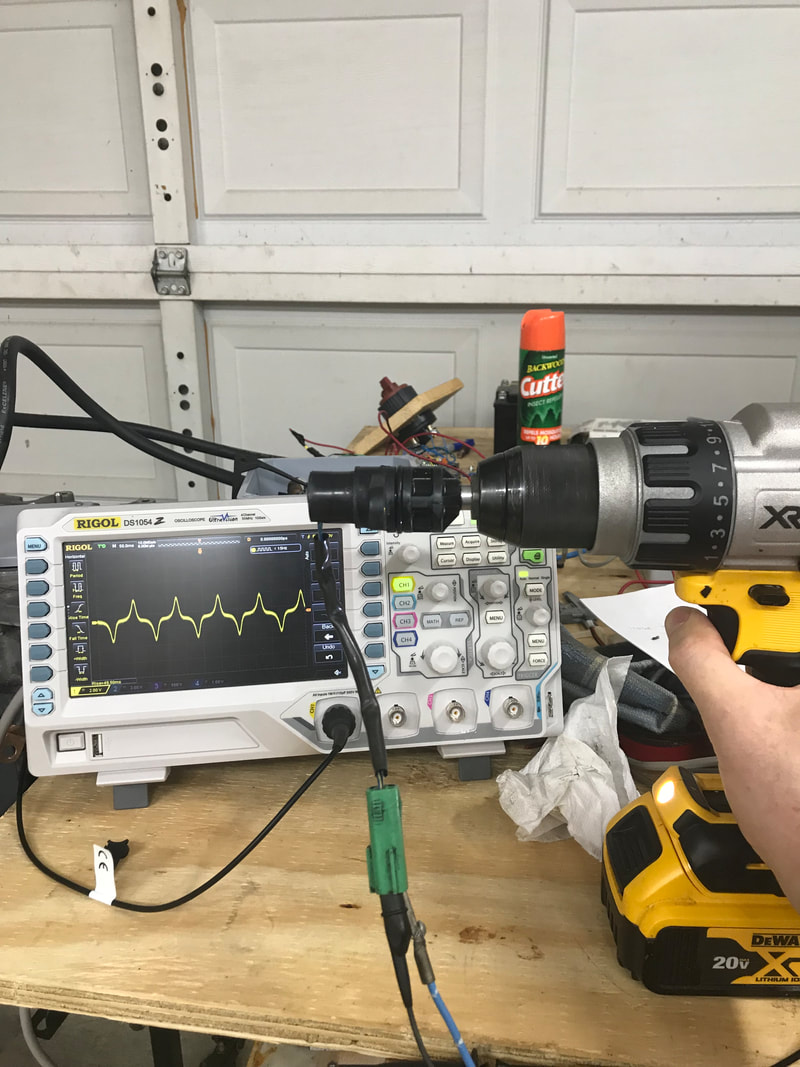

Hello Electrified Miata and Formula-Mazda-E Fans! It's been two weeks since the last update on these projects. The fifth and final battery has been assembled. I attempted to merge the go-kart and Leaf motor software, resulting in update hell. We used an axe to test safety procedures. Join us on the journey to make the tires go fast, safely, quietly and efficiently! Electrified Miata News: At the last update, we were working on the fifth and final battery. Eric and Nolan installed all the studs and earn a few blisters for their efforts 'screwing around'. With the hard work done, I could 'get nutty' and install the 422 locking nuts. This particular battery will be installed vertically which is why it has so many studs. With all the batteries assembled, it was time to construct a mobile battery holder. Why mobile, you might ask? While I don't anticipate another battery fire, accidents do happen. It would be much easier to move 300lbs of batteries if they are on wheels! Brian and Bruce worked on this task and made a simple, but highly functional design using the old wooden go-kart ramp. One problem with wheeling the batteries out of the garage is the two large thick wires that connect the pack to motor/transmission and Pi's. Every extra connection adds resistance, heat and a possible failure point into the system. However, in an emergency, the batteries need to be disconnected quickly. Our first attempt at a quick disconnect was using an axe on the cable. One swing of the axe could cut 90% of the cable, but the remaining 10% would still tie the batteries to the rest of the project. After a few tries by both Bruce and Brian with a freshly sharpened axe we gave up. We could use a larger axe or we could use the angle grinder with a cut-off wheel. The angle grinder is more controlled and nearly as fast, so we'll keep one handy when using the battery pack. You might ask, why aren't the batteries being installed in the car? They still need one more piece to be complete. Each battery needs the BMS modules installed, so the battery can be monitored. Joe worked through the remaining issues and released a software version that has the same functionality as the previous revision. However, we'll need 100 of these boards. Installing the firmware is a big job done 100 times. In addition, Joe tests each board. To do firmware installation and testing repeatedly, he built a test fixture. The test fixture needs updated because of the new board design. Joe has finished this and we're waiting for the new test fixture boards to arrive. Here is the picture of the latest BMS boards. Wow, car night arrived in a hurry this last week. I knew I had a challenge to get the Leaf motor software integrated with the eMiata base software. I couldn't directly re-use the older Leaf motor software because contactor control hardware had been moved and tested on the kart. That will require some software changes to accommodate the updated hardware configuration. In addition, the previous go-kart software was many versions ahead in both the operating software as well as my own software. As soon as I got the 3 kart Pi's talking with the motor controller Pi, I ran into operating system version differences. I thought, "no problem, simply update the Pi". I ran the update, and chug, chug, chug, Splat. The update failed, and the motor controller Pi would no longer boot! Four hours later, the newest OS was installed along with replicating most of the CAN driver. I needed to update the 3 ex-go-kart Pi's to match versions with the newly update motor controller Pi. By the time I started testing my software and re-writing for the new contactor configuration, time had flown by. The software wasn't ready by the time car night happened. Sigh. Luckily, there was plenty of other things to keep us entertained. Joe came to car night and I wanted to nail down the details for the transmission speed sensing circuit. Soon, we'll be spinning the motor and testing computer assisted shifting. Testing requires the speed sensor working. I had the Pico (a micro-controller) working at lower speeds (19,200 baud rate) and wanted to see the timing of the speed sensor. Joe looked at the circuit and gave me pointers and suggestions. Thank you Joe for guiding me in the right direction! Then we decided to test the speed sensor. Since the software wasn't ready to spin the motor, we grabbed the drive shaft and turned the transmission by hand. However, we really didn't see much of a signal on the scope? Did the sensor need power? Neither Joe or I thought so and Bruce confirmed it. Broch located a replacement sensor for $34 on eBay and Joe found a newer one for $100. Brian removed the non-working sensor from the transmission, took the gear off and we spun the sensor using a drill. Still no signal! Rats. While playing with the sensor, the wires fell off, giving me a big hint of why we saw no signal. Brian, with admirable patience and skill using a Dremel, removed the potting goo so we could see and access the contacts. Joe then hooked it to a scope and we could see a strong signal! Whoo Hoo. The sensor can be re-soldered and fixed. While we were playing with sensor, Bruce and Nolan installed connectors on the new cable, and connected all the batteries modules in series. Measuring with the meter, we see 357.7 volts on the pack. Thank you Bruce and Nolan for hooking up the power and dealing with one of the riskier parts of this venture! If only the software was ready, sigh.. However, I do like when there is nothing stopping progress but my own code. With all that power, its good to have an "OFF" switch in the circuit. Brian mounted up the master 'Kill' switch that we'll use in the car. This will allow us to turn the circuit off! Thank you Brian for mounting the switch. Formula Mazda-E News:

Broch sent off the second set of drawings to Send-Cut-Send to verify the correct dimensions for the trans-axle end of the coupler. We've ordered the batteries, BMS and lots of battery box assembly parts. Now we do the hardest part, wait! For the Formula Mazda-E next week, we'll also order the steel needed to physically mount the batteries to the car. For the Electrified Miata, we'll get the software running to start working out the wires, bits and bytes of rev-assisted shifting. As always, thanks for reading!

0 Comments

Leave a Reply. |

AuthorBill likes cars that understand the 'go fast now' pedal. Archives

May 2022

Categories |

Proudly powered by Weebly

RSS Feed

RSS Feed